Via 3D printing technology, the Car thermal system cooling fan mold cooling time can be shorten from original cooling time 28S to 12S, ±23S, that is, 9 ~ 15S. And if assembly 3D inserts, the cooling cycle can basically reach the anticipate acceptance standard 9~12s;the efficiency and speed can also reach the expected improvement.

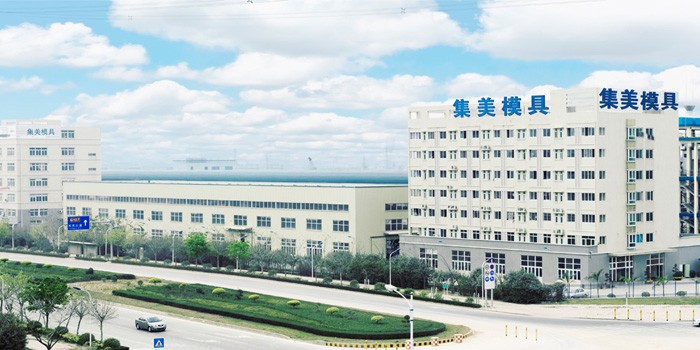

Through many years of experience in design and cooperation with overseas customers, Jimei has accumulated a wealth of knowledge, the mold production has reached the precise mold standards of the United States and Europe.

Surface treatment: VDI 3400 Code, SPI finish standard, MOLD-TECH, textured surface, polish etc. Software: UG/ Solidworks / Pro-E / Moldflow/ Plastics Insight etc.

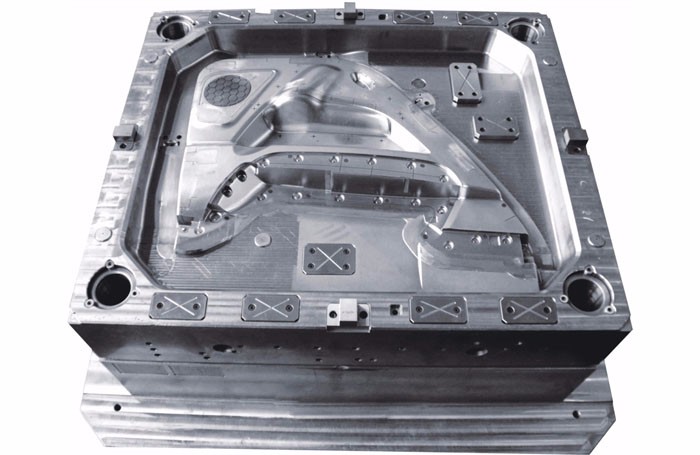

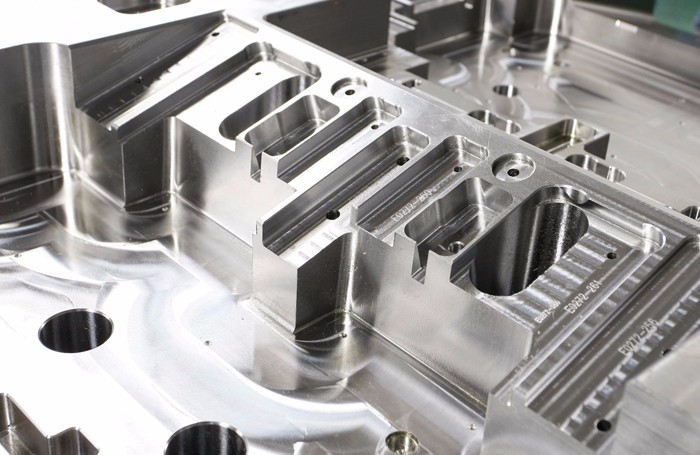

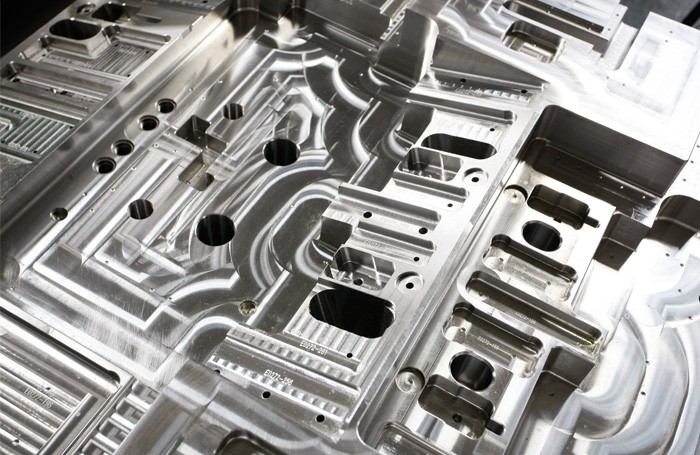

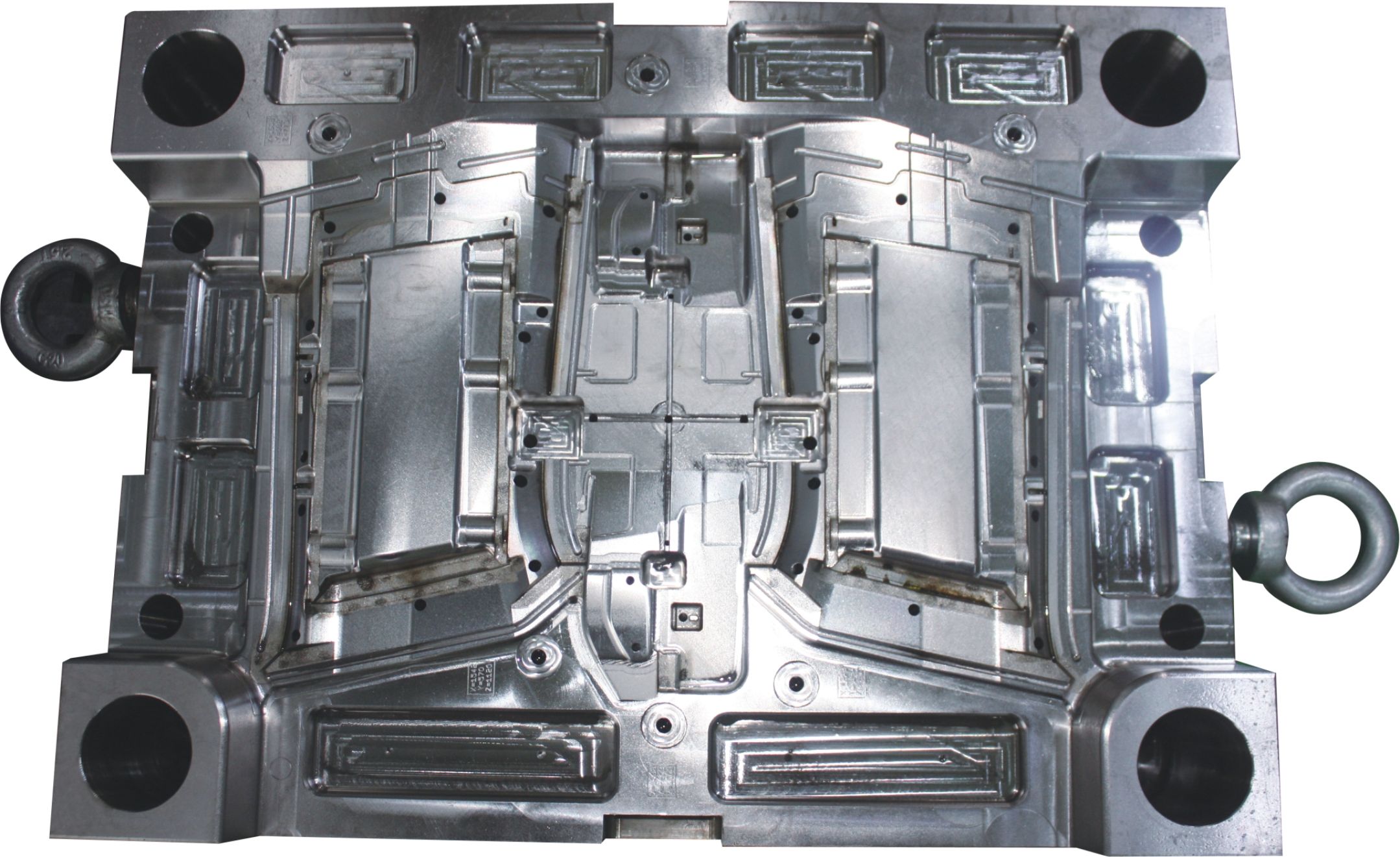

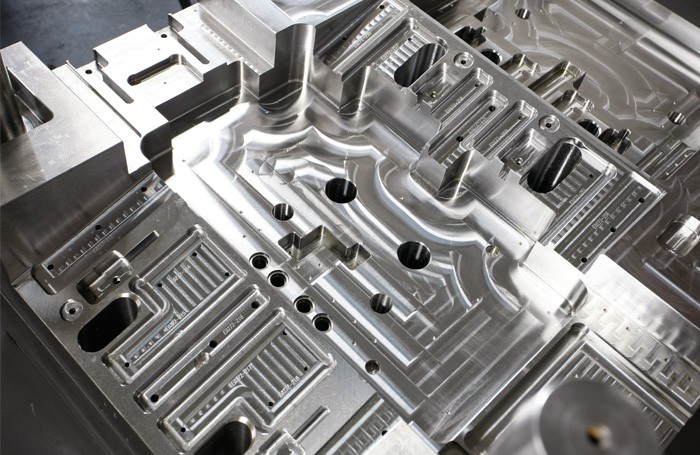

The injection mould of automobile parts is manufactured with high precision CNC equipment, the highest spindle speed reaches 24000RPM and the precision reaches 0.02mm thimble hole.Oblique top hole and so on are cut with high precision WEDM. The highest precision could be 0.005mmm.

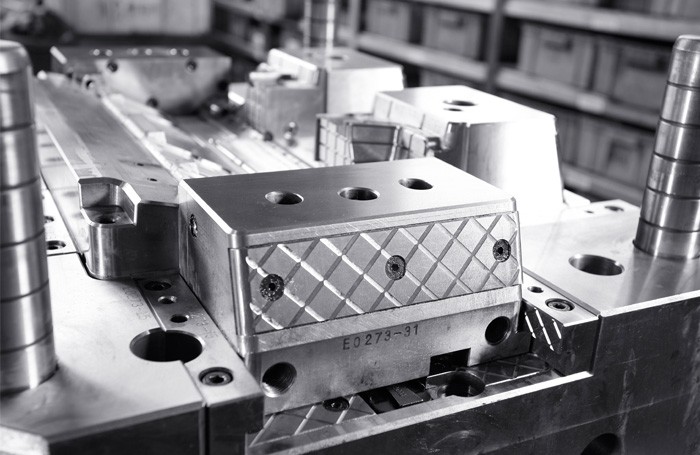

According to the customer's needs, all injection mold sliders use wear-resistant steel blocks, and each piece will be engraved corresponding number. Jimei introduces the ERP production management system and provides a schedule once a week, Let customer even the stay at home can also know the progress of the project.From customer orders to mold delivery,the whole process is transparent.

According to the customer's needs, all injection mold sliders use wear-resistant steel blocks, and each piece will be engraved corresponding number.

Adopt good performance steel to manufacture mould, the mould life can reach 500,000 times to 1 million times. High precision machining equipment, so as to ensure the precision of the mould workpiece.The mold which made by JIMEIi has the interchangeability between the workpiece and the mold, reducing the time in the production process, and convenient for the customer to use in the injection molding production.

Whether in mould design, mould manufacture or mould inspection,the impact of these steps on injection molding will be noticed, which enables our cross-departmental communication more smooth and provide better technical support to customers.

Shenzhen Jimei Mold technology Co.,Ltd. is one of Shenzhen Machinery Association member and governing units and established in year 2004 with 30 million RMB registered capit...

Automobile Part general material: PP-TD20,POM,PC+ABS,ABS etc. Injection Mould Material: P20, H13,718,S136, 1.2311, 1.2738, NAK80, 2344, 2083 ect.

Automobile Part general material: PP-TD20,POM,PC+ABS,ABS etc. Injection Mould Material: P20, H13,718,S136, 1.2311, 1.2738, NAK80, 2344, 2083 ect.

How the plastic part is produced?: Put the plastic particles into the hopper, heat it into liquid plastic in the barrel, and then put the plastic into the cavity by pressure, after the part is cooled and solidified,open the mould,then the product will be ejected, a plastic part process is completed.