Plastic Injection Mold Suppliers

Mould Size : Middle-Large Size

Quality Guarantee : SO9001:2008 & ISO14001:2004

Lead Time : 25-60 days, on basis of mold complexity.

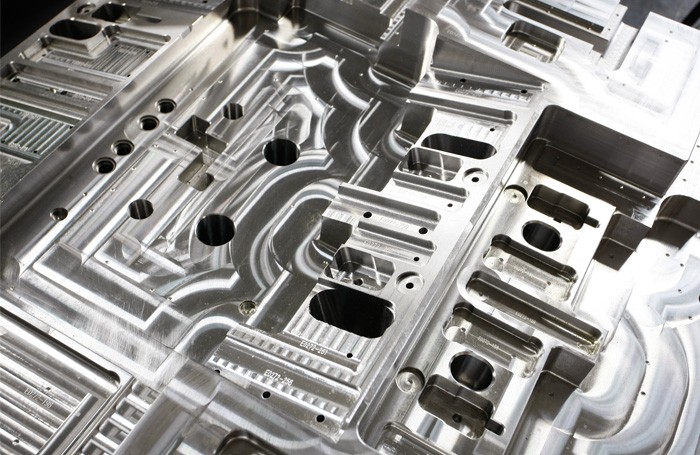

The injection mould of automobile parts is manufactured with high precision CNC equipment, the highest spindle speed reaches 24000RPM and the precision reaches 0.02mm thimble hole.Oblique top hole and so on are cut with high precision WEDM. The highest precision could be 0.005mmm.

Injection Mold Material: P20, H13,718,S136, 1.2311, 1.2738, NAK80, 2344, 2083 ect.

Mold cavity number: Single cavity, Multiple cavity ,interchangeable inserts cavities or one mold with different products

Runner system: Hot runner , Cold runner etc.

Main process: Milling, grinding, CNC, EDM, wire-electrode cutting, electrospark, lathe, etc

Surface treatment: VDI 3400 Code, SPI finish standard, MOLD-TECH, textured surface, polish etc.

Software: UG/ Solidworks / Pro-E / Moldflow/ Plastics Insight etc.

Software: UG/ Solidworks / Pro-E / Moldflow/ Plastics Insight etc.

The injection mould of automobile parts is manufactured with high precision CNC equipment, the highest spindle speed reaches 24000RPM and the precision reaches 0.02mm thimble hole.Oblique top hole and so on are cut with high precision WEDM. The highest precision could be 0.005mmm.

CNC automatic drilling machine is a very advanced machining method, it mainly uses the cutter along a vertical axis or an angle to work up and down, and the workpiece is safely fixed on the lathe and then moving from left to right and moving up and down along two shafts. CNC computer is also a very advanced machining method,which is mainly used in the machining of rotating parts. The cutting tool is cutting along two axes or one angle of horizontal line. The workpiece is safely fixed on the lathe and the drilling tool operates clockwise or counterclockwise.