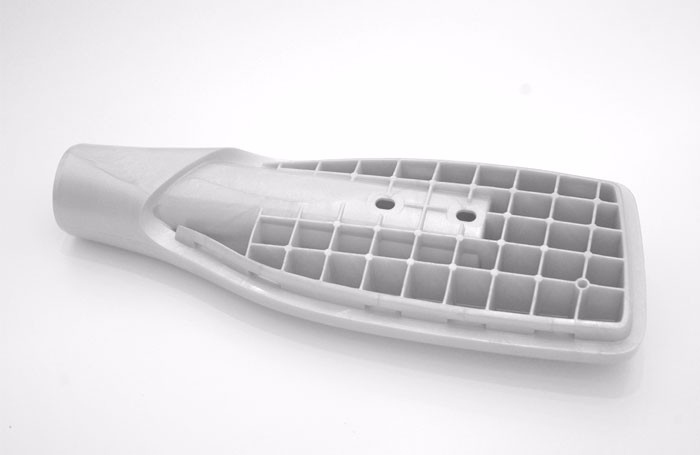

Automobile parts mold

Mould Size : Middle-Large Size

Quality Guarantee : SO9001:2008 & ISO14001:2004

Lead Time : 25-60 days, on basis of mold complexity.

Automobile Part general material: PP-TD20,POM,PC+ABS,ABS etc.

Injection Mould Material: P20, H13,718,S136, 1.2311, 1.2738, NAK80, 2344, 2083 ect.

Mould cavity number: Single cavity, Multiple cavity ,interchangeable inserts cavities or one mould with different products

Runner system: Hot runner , Cold runner etc.,as per customers requirement and part structure

Main process: Milling, grinding, CNC, EDM, wire-electrode cutting,electrospark, lathe, etc

Surface treatment: VDI 3400 Code, SPI finish standard, MOLD-TECH, textured surface, polish etc.

Software: UG/ Solidworks / Pro-E / Mouldflow/ Plastics Insight etc.

JIMEI provides one-stop service. Senior designers with 10 years of experience in mould industry will give a comprehensive analysis for the moulding process, mould structure and manufacturing process of the customer's products. We design the cavity according to the shape and function of the product, which will use for forming the product. And also will design the complete mould structure and machining parts for our customers, perfect assembly requirements and injection process requirements. Before opening mould, JIMEI will fully analyze the plastic parts appearance quality defects (such as shrinkage) or mould structure problems (such as parting line setting, gate setting. mould life can not be guaranteed and so on, JIMEI use 22 strict inspection procedures to ensure the quality of the mould and the mould appearance without rust, no impact, no module defects such as incomplete. When the mould delivery, JIMEI will provide a set of mould related information.