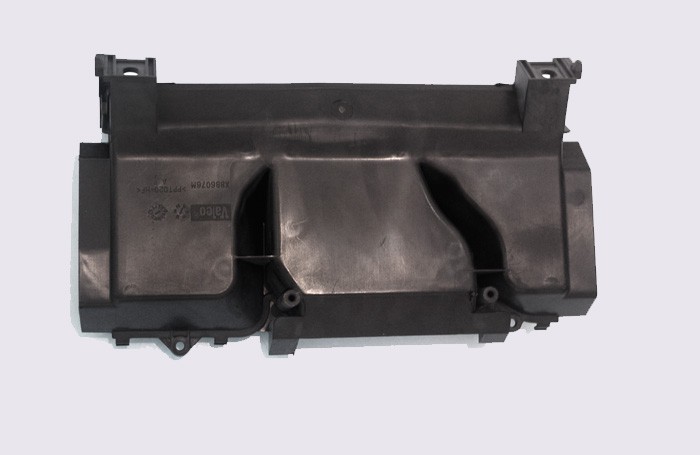

Automobile Heat System Injection Mold

Mould Size : Middle-Large Size

Quality Guarantee : SO9001:2008 & ISO14001:2004

Lead Time : 25-60 days, on basis of mold complexity.

Automobile Part general material:PP-TD20,POM,PC+ABS,ABS etc. Injection Mould Material: P20, H13,718,S136, 1.2311, 1.2738, NAK80, 2344, 2083 ect.

Automobile Part general material: PP-TD20,POM,PC+ABS,ABS etc.

Injection Mould Material: P20, H13,718,S136, 1.2311, 1.2738, NAK80, 2344, 2083 ect.

Mould cavity number: Single cavity, Multiple cavity ,interchangeable inserts cavities or one mould with different products

Runner system: Hot runner , Cold runner etc.,as per customers requirement and part structure

Main process: Milling, grinding, CNC, EDM, wire-electrode cutting,electrospark, lathe, etc

Surface treatment: VDI 3400 Code, SPI finish standard, MOLD-TECH, textured surface, polish etc.

Software: UG/ Solidworks / Pro-E / Mouldflow/ Plastics Insight etc.

JIMEI has a complete mould production monitoring ERP system, from order to delivery, professional one-to-one "housekeeping" order tracking service, can report order situation to customer in real time, let customers "manage" JIMEI injection moulding factory in zero distance. JIMEI owns the 20000 square meters industrial park, a large-scale production base, allocating strong R & D , production, and sales team. We built up several production lines to guarantee the delivery time. Rich experience allows us to make injection mould more reasonable, more efficient, greatly reduce the cost of post-production.