Middle-large Size Luggage Injection Molds

Mould Size : Middle-Large Size

Quality Guarantee : SO9001:2008 & ISO14001:2004

Lead Time : 25-60 days, on basis of mold complexity.

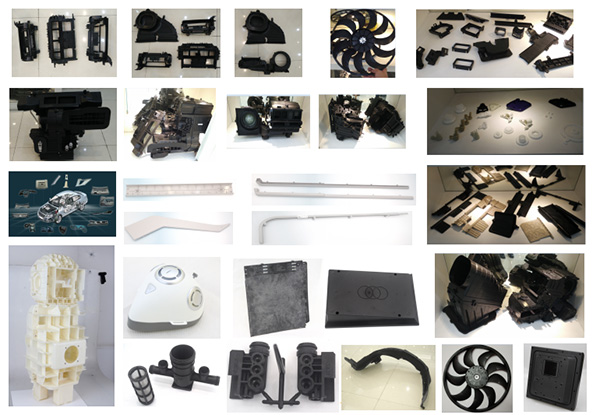

Luggage case material: PP、ABS+PC、ABS etc.

Injection Mould Material: P20, H13,718,S136, 1.2311, 1.2738, NAK80, 2344, 2083 ect.

Mould cavity number: Single cavity, Multiple cavity ,interchangeable inserts cavities or one mould with different products

Runner system: Hot runner , Cold runner etc.,as per customers requirement and part structure

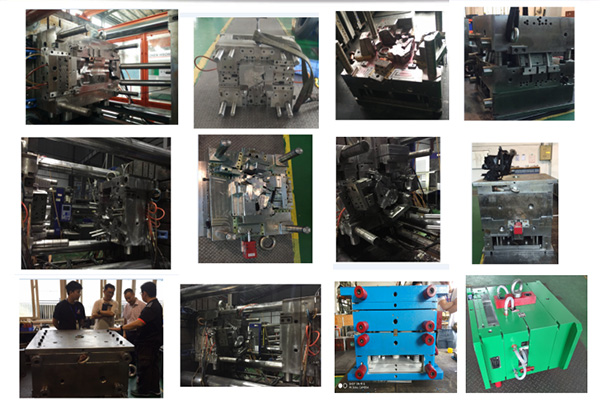

Main process: Milling, grinding, CNC, EDM, wire-electrode cutting,electrospark, lathe, etc

Surface treatment: VDI 3400 Code, SPI finish standard, MOLD-TECH, textured surface, polish etc.

Software: UG/ Solidworks / Pro-E / Mouldflow/ Plastics Insight etc.

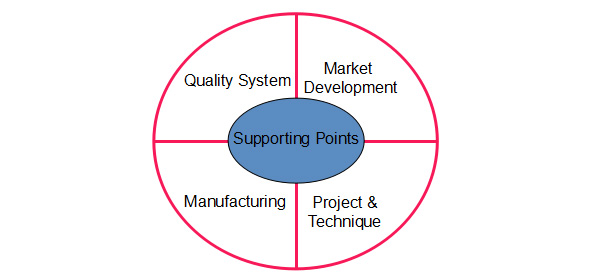

JIMEI has the professional ability of professional OEM/ODM, and has established a perfect quality support system. Our company always adheres to the concept of "high quality, on time, reasonable price and credible service ", devoting to mould manufacture and injection moulding of automobile parts, electronic & electrical equipment, medical equipment and household electrical appliance equipment, ect. What's more, we would try our best to finding out the shortage and defect in design, and propose solutions to customers so as to shorten the product design cycle, and to seize the opportunity for your product in market.

The R&D Department of JIMEI mould&plastics factory adopts PRO/E, UG, MASTERCAM and other software to carry out design and optimization of production and mould structure. In the mould production process, we pay attention to the design review and strict on-site management, trying to normalize mould production according with mould drawing strictly, and supervised by engineers who has a dozen year of practical experiences. Now, our mould production exported to the United States, Britain, Germany and other developed countries and has made a good international reputation.

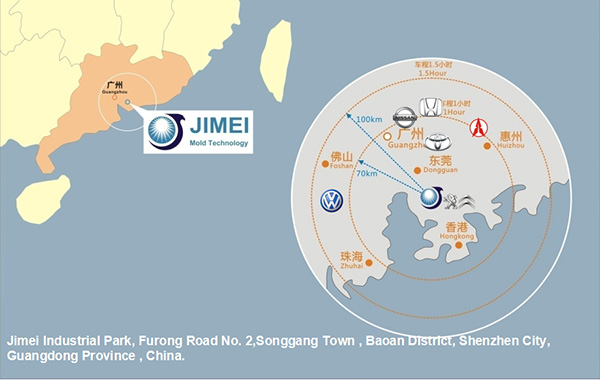

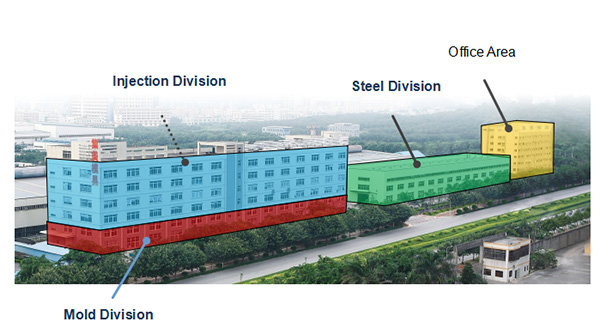

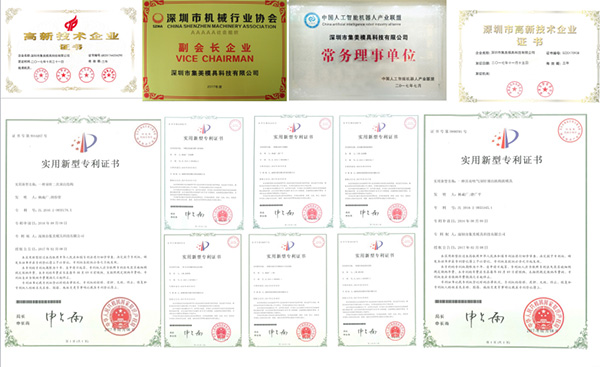

Shenzhen Jimei Mold technology Co.,Ltd. is one of Shenzhen Machinery Association member and governing units and established in year 2004 with 30 million RMB registered capitals,which mainly devoted in injection mold,design and manufacturing.We own the factory covers more than 20000 square meters.

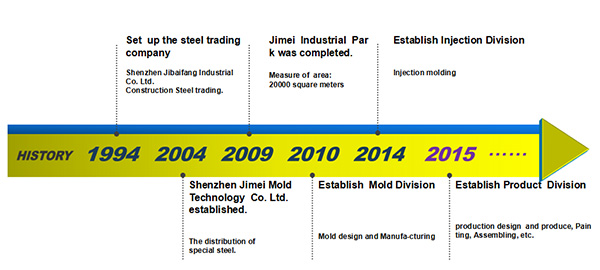

Company Development History:

Company Location:

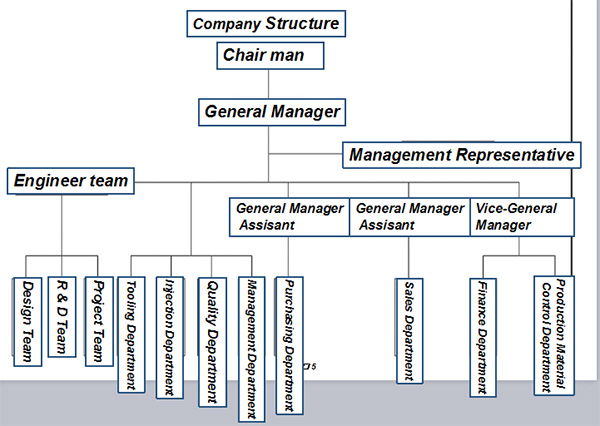

Copmany Devision and structure:

Company profile:

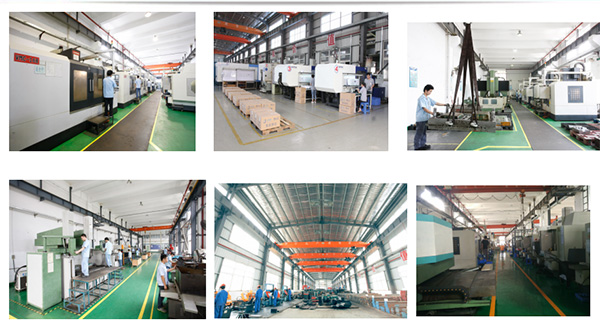

Company workshop (Including mold workshop and injection workshop):

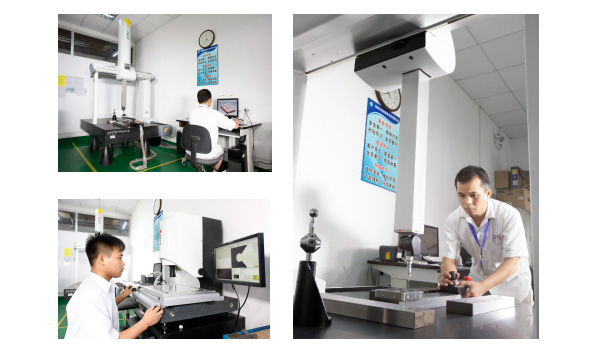

Company equipments:

Jimei has high precision vertical, CNC machine, Horizontal CNC machine, gantry machining-center, Double-end EDM Machine, Injection Machine, Die spotting Machine,Wire-Cutting Machine. Digital Control Lathe,Numeric Control Milling Machine,High Precision Grinding Machine and other equipment, besides we have CMM 3D inspection machine,Project machine and other accurate inspection device. In order to let our company integrated with world we build a team consist of experienced engineer which could satisfy any demand you required and got good reputation from Southeast Asia,Europe,and other markets.

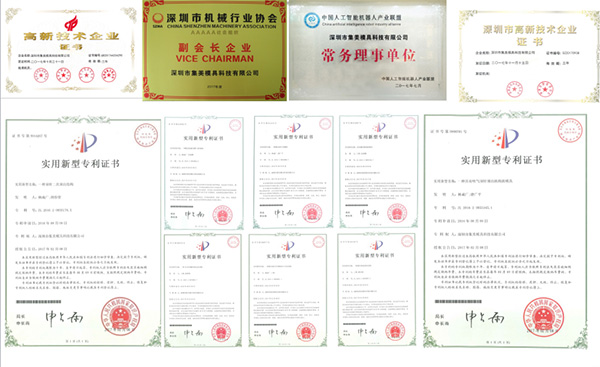

Jimei has obtained ISO9001 and ISO14001 certification:

Company honor:

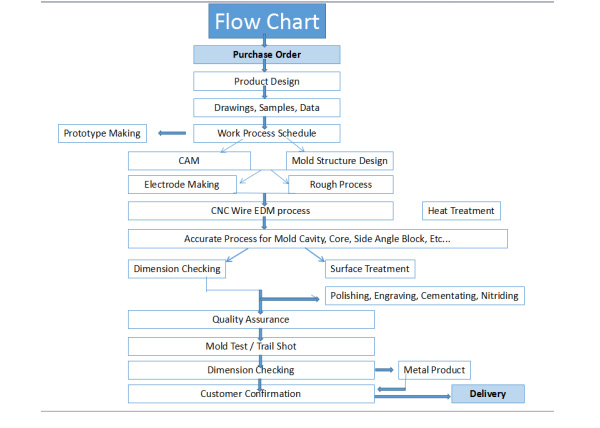

Injection mold manufacturing flow chart:

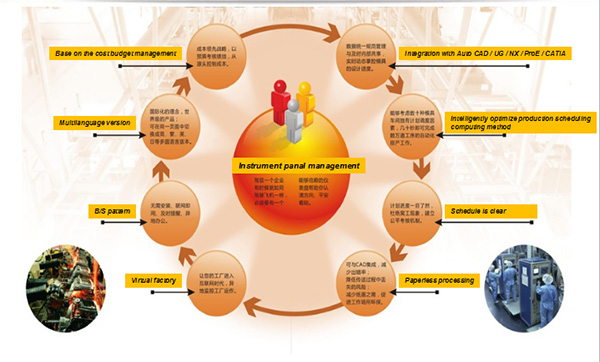

Prodution management of injection mold---ERP System:

As is known that a good quality mold mostly depend on the mold design process, we pick the most advantage CAD/CAM/CAE software to implement the difficulty in mold design. Besides we use the UG/ Solidworks / Pro-E / Moldflow/ Plastics Insight to analyze the mold to check if it have warpage discoloration/ water ripple / sink mark / warpage / short shot etc. In this way we not only can achieve high efficiency drawing but also can manufacturing a high quality and more precision mould.

Project management:

1. Carry out responsibility system of project manager, follow the project with customer.

2. For the issues during the design and production, established system of project evaluation, all solutions should get the approval by customer before implementation.

3. Provide project schedule and progress report on a regular basis.

4. Coordinate the engineering change and communicate its feasibility analysis with customer.

5. Review the samples and summarize the issues.

6. Continuous improvement and absorbing the experience.

The front-end customer support:

1.The early stage of the product development and design, have professional engineers to participate in it.

2. Actively cooperate with the confirmation of preliminary model effects.

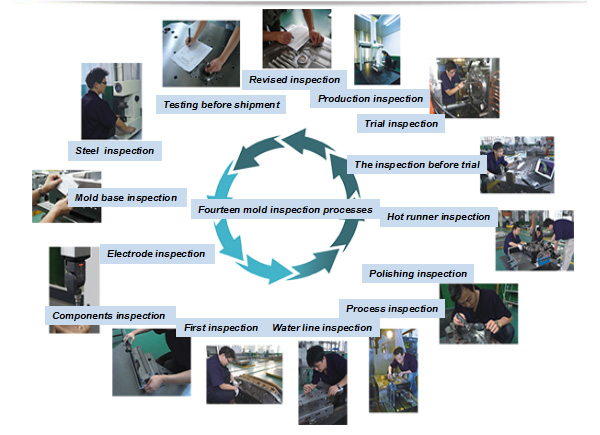

The flow chart of QC and quality inspection flow:

The product we main manufacturing including Automotive,Medical Appliance,Household appliances, Electronic & Electrical Equipment,Robot,Passenger Aircraft Interior Parts and other related products.

Mold show:

Injection product show:

Way of packing:

Our Customers:

Our Suppliers:

The area of sales market:

We have established strong credit and working relationship with our current clients who are in the United States, the United Kingdom, Canada and some southeast Asian countries.

Customers visit our company:

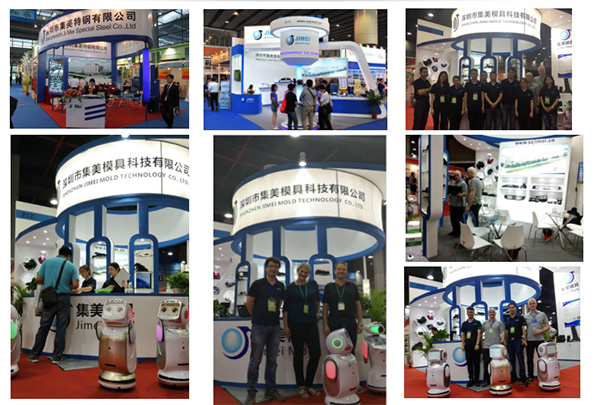

Company exhibition:

Aoccrding to Jimei’s mind identity “pursuit of excellence, superior yourself”, Jimei always arranges variety or interesting activities, like public service,traveling and training courses.We are continuing to enhance our enterprising spirit.

Jimei sincerely look forward to cooperation with you!