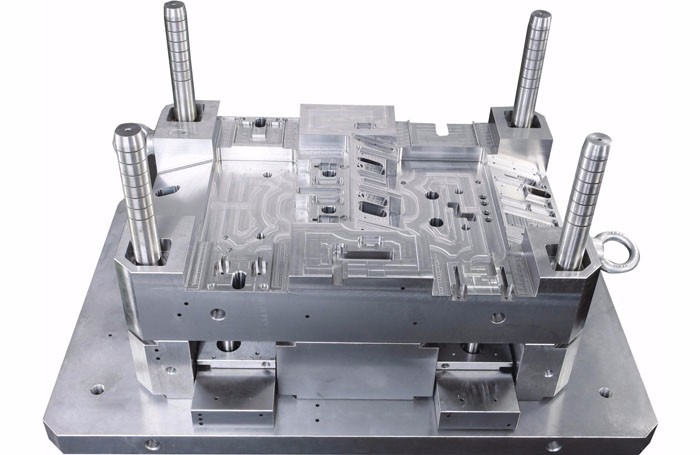

Injection Molding Services

Mould Size : Middle-Large Size

Quality Guarantee : SO9001:2008 & ISO14001:2004

Lead Time : 25-60 days, on basis of mold complexity.

With a full set of advanced mould manufacturing and processing equipment, such as CNC, EDM, digital controlled lathe, processing centre, injection machine, wire cutting machine, milling machine, electrical discharge machine, grinding machine,CMM 3D inspection machine ect, JIMEI have the ability to complete a set of procedure which including mould design,insert processing, mould assembly, trial mould ect.

Injection Mold Material: P20, H13,718,S136, 1.2311, 1.2738, NAK80, 2344, 2083 ect.

Mold cavity number: Single cavity, Multiple cavity ,interchangeable inserts cavities or one mold with different products

Runner system: Hot runner , Cold runner etc.

Main process: Milling, grinding, CNC, EDM, wire-electrode cutting, electrospark, lathe, etc

Surface treatment: VDI 3400 Code, SPI finish standard, MOLD-TECH, textured surface, polish etc.

Software: UG/ Solidworks / Pro-E / Moldflow/ Plastics Insight etc.

With a full set of advanced mould manufacturing and processing equipment, such as CNC, EDM, digital controlled lathe, processing centre, injection machine, wire cutting machine, milling machine, electrical discharge machine, grinding machine,CMM 3D inspection machine ect, JIMEI have the ability to complete a set of procedure which including mould design,insert processing, mould assembly, trial mould ect.