3D Printing injection Mold

Mould Size : Middle-Large Size

Quality Guarantee : SO9001:2008 & ISO14001:2004

Lead Time : 25-60 days, on basis of mold complexity.

Via 3D printing technology, the Car thermal system cooling fan mold cooling time can be shorten from original cooling time 28S to 12S, ±23S, that is, 9 ~ 15S. And if assembly 3D inserts, the cooling cycle can basically reach the anticipate acceptance standard 9~12s;the efficiency and speed can also reach the expected improvement.

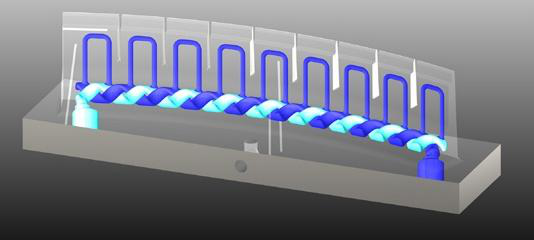

3D printing Car thermal system cooling fan mold

1 . Setting contrast between cooling system and pouring system

Scheme 1: Cooling system: ordinary cooling water route;

Gating system: 9 drops feed

Scheme 2 : Cooling system: 3D printing cooling water system;

Gating system: 11 drops feed

2 . Mold temperature comparison

Compared with the same position, the effect of 3D water cooling is about 7~9 C higher than that of ordinary water transport.

Basically, the heat dissipation of the two schemes is fairly uniform, but the heat dissipation efficiency of 3D water transportation is higher.

3. Comparison of product arrives ejection time (runner system)

The efficiency of 3D water transfer heat dissipation is higher than that of ordinary water transport. The difference between the two schemes is about 16s.

4.Shrinkage of product volume

In the same position, compared with the shrinkage rate, the 3D water transport is about 0.2%~0.4% smaller than that of ordinary water.

5.Deformation

The cooling of 3D printing water route is uniform, and the shrinkage deformation of the product in the same position is less than about 0.1mm of normal water route.

Conclusion:

Via 3D printing technology, the Car thermal system cooling fan mold cooling time can be shorten from original cooling time 28S to 12S, ±23S, that is, 9 ~ 15S. And if assembly 3D inserts, the cooling cycle can basically reach the anticipate acceptance standard 9~12s;the efficiency and speed can also reach the expected improvement.