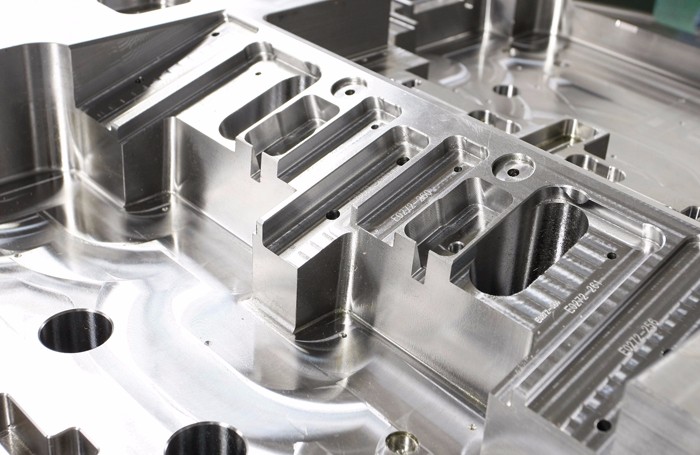

Plastic Injection Molding Service

Mould Size : Middle-Large Size

Quality Guarantee : SO9001:2008 & ISO14001:2004

Lead Time : 25-60 days, on basis of mold complexity.

Surface treatment: VDI 3400 Code, SPI finish standard, MOLD-TECH, textured surface, polish etc. Software: UG/ Solidworks / Pro-E / Moldflow/ Plastics Insight etc.

Injection Mold Material: P20, H13,718,S136, 1.2311, 1.2738, NAK80, 2344, 2083 ect.

Mold cavity number: Single cavity, Multiple cavity ,interchangeable inserts cavities or one mold with different products

Runner system: Hot runner , Cold runner etc.

Main process: Milling, grinding, CNC, EDM, wire-electrode cutting, electrospark, lathe, etc

Surface treatment: VDI 3400 Code, SPI finish standard, MOLD-TECH, textured surface, polish etc.

Software: UG/ Solidworks / Pro-E / Moldflow/ Plastics Insight etc.

Plastic injection mold is one of the most common molds in the production of thermoplastic parts. Plastic processing equipment used for plastic injection molding is an injection molding machine, the plastic is melted in the heating barrel, and then feed into the mold cavity with screws or the injection system of the plunger, the injector nozzle and the mold gating system, and the plastic is molded, cooled, hardened , finally stripped to get the product.

At present, Jimei has capacity to manufacture maximum size 2.5 meters and 20 Ton weight injection mold.