ERP System

1. Production Management- ERP System: How it works?

Jimei introduced ERP production management system, From the initial order to the final delivery, the whole process applies information management.

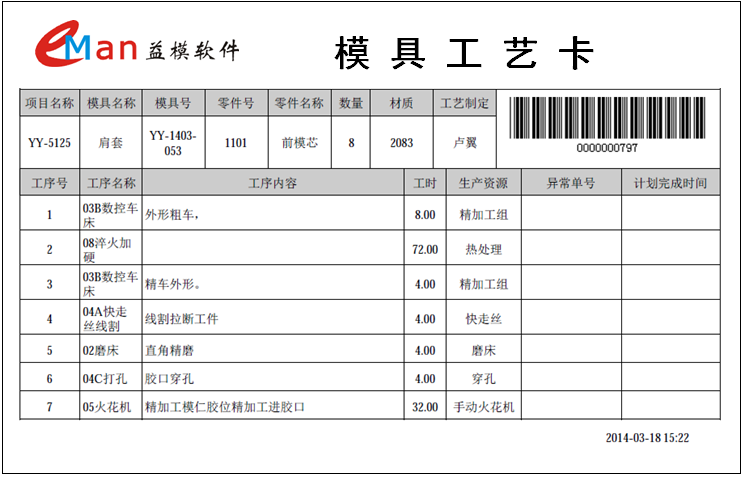

Computer-Aided Process Planning

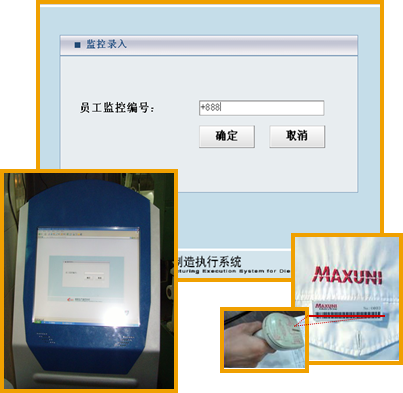

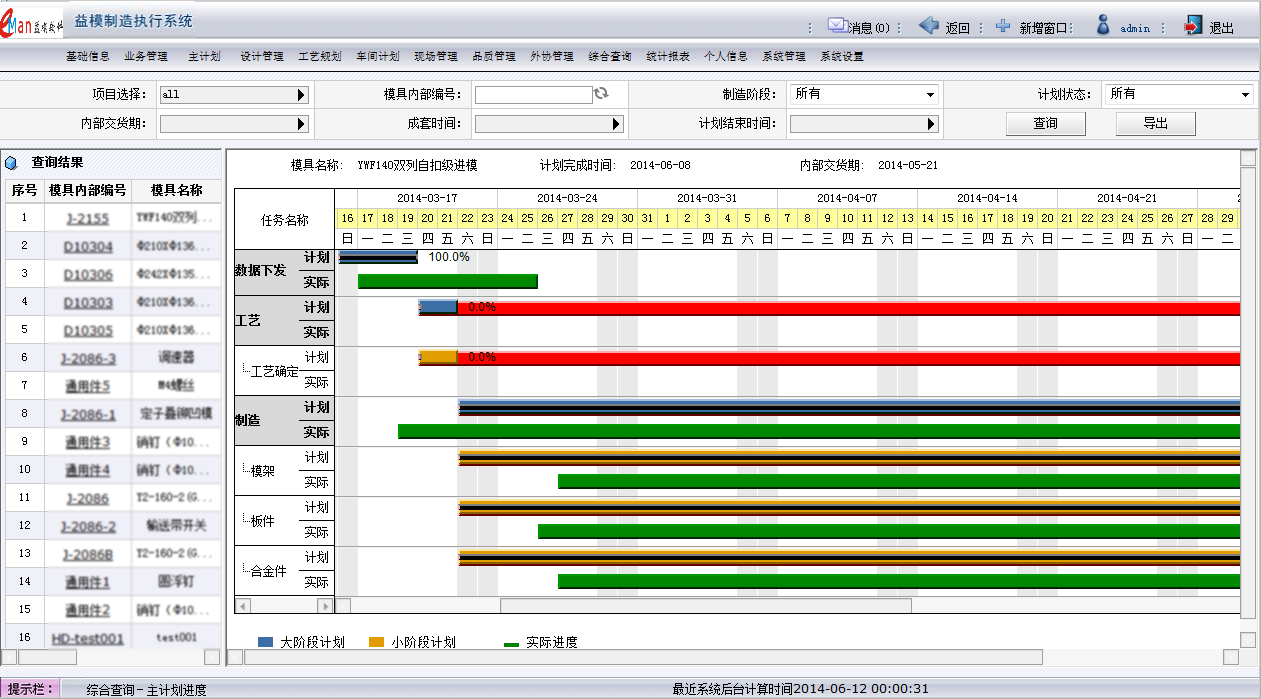

Each new project will create a custom process card and automatically generate a monitoring bar code. The production manager can manage the whole project schedule by Gantt chart. The parts are associated with the bar code and the part mark is unique. Through the bar code collection in the workshop, the comparison table of the process time and the actual working hours will be produced, the accuracy of the estimated working hours can be continuously improved. To get the utmost out of equipment and workers' labor force. In order to improve the efficiency of mould manufacturing, the sequence of machining components such as combination machining, split machining, discharge machining and CNC machining is fully considered.

The rapid clamping system is also equipped to improve the process efficiency and also could reduce the error rate of electrode flow in mold manufacturing and processing.

Process Card

Mold main plan progress list

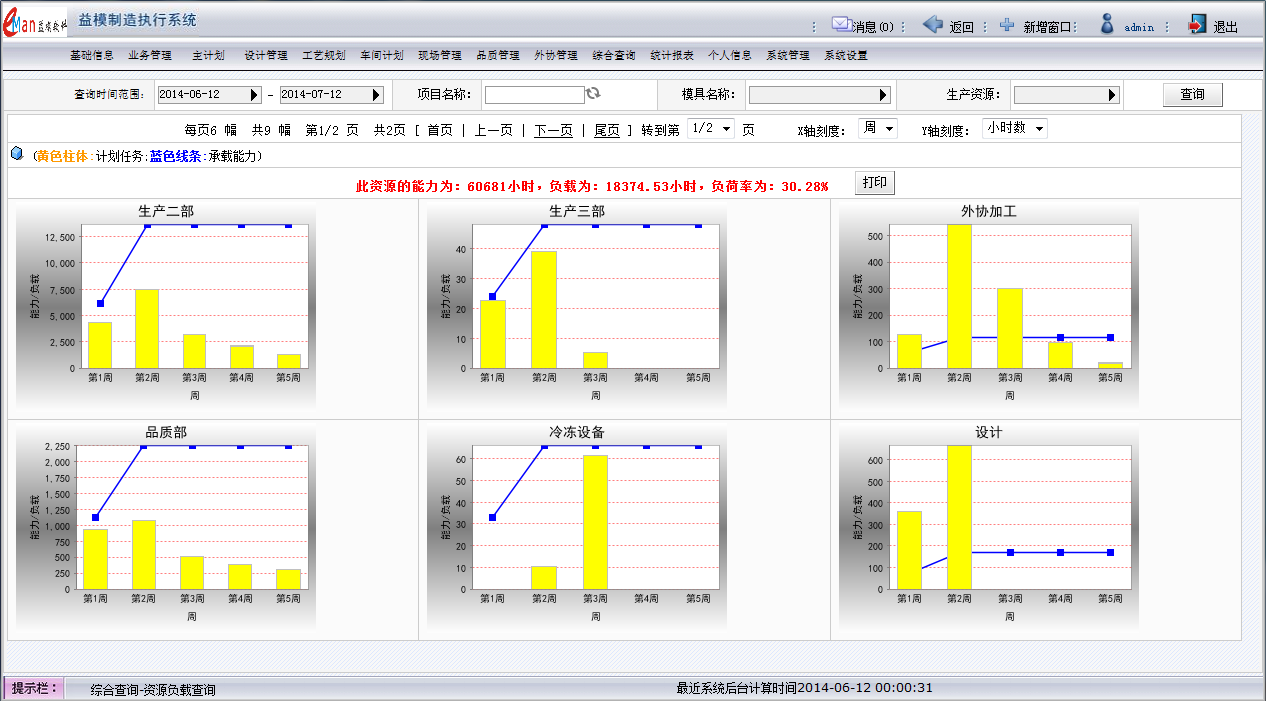

Resources load statistical chart

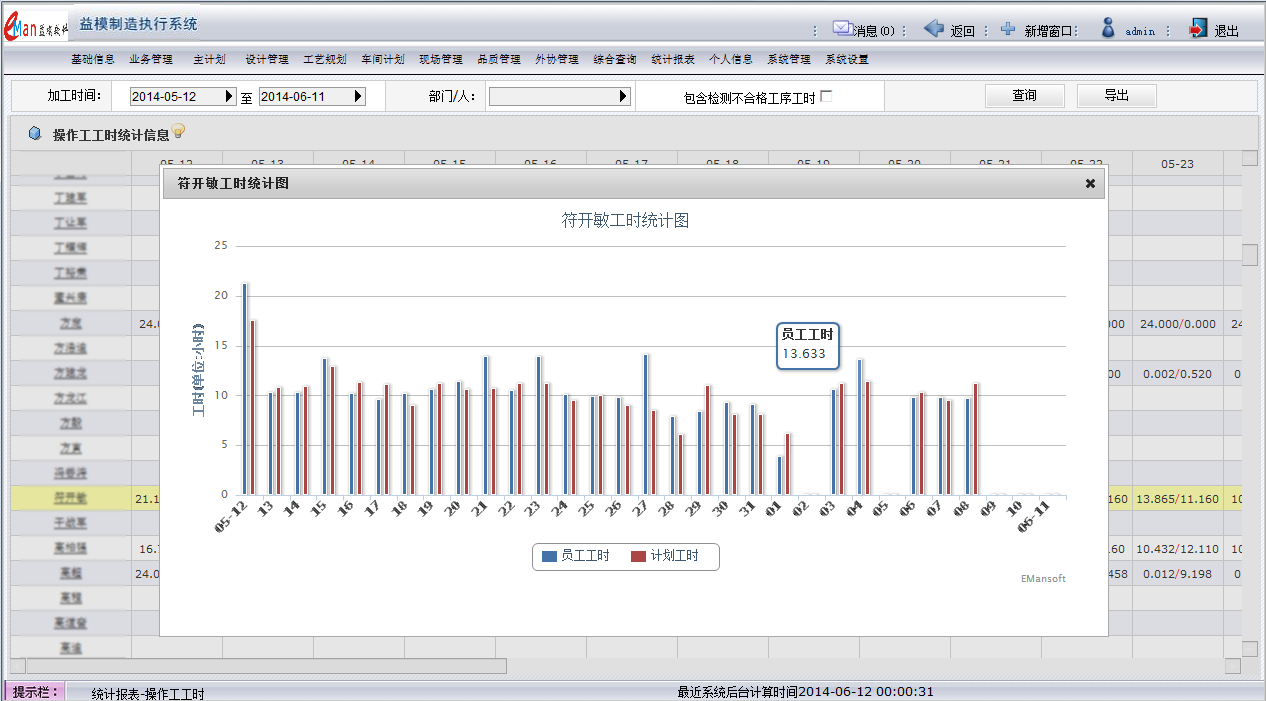

![]() Operation time table

Operation time table

Mature production supervision system

The production personnel can perform the production plan on the ERP terminals at the workshop through simple operation, and feedback to the actual processing information. The managers can instantaneously view and control the up-to-date parts processing status, mold schedule and order progress etc.

Jimei has a comprehensive project management system.

We carry out responsible system of project manager , and has a over-all project review system.Project supervisor will regular reports the project progress、puts forward feasibility analysis for project adjustment、reviews the sample to solve the problem in time, Jimei will keep continuous improvement and tries our best to make our customers satisfy.

Istantaneous mold plan performance tracking

Jimei has obtained the ISO9001:2008 quality management system certification, ISO14001:2004 environmental management system certification. Jimei also has a special QC department, and equipped with CMM three-coordinate measuring instrument, two - dimensional projector and other high-tech testing equipment.In Jimei, every key component of parts will be tested in all directions to ensure the quality of the mold. Before the mold is shipped, Jimei will send inspection report for customer approval and the full set of relevant mold information will be provided.

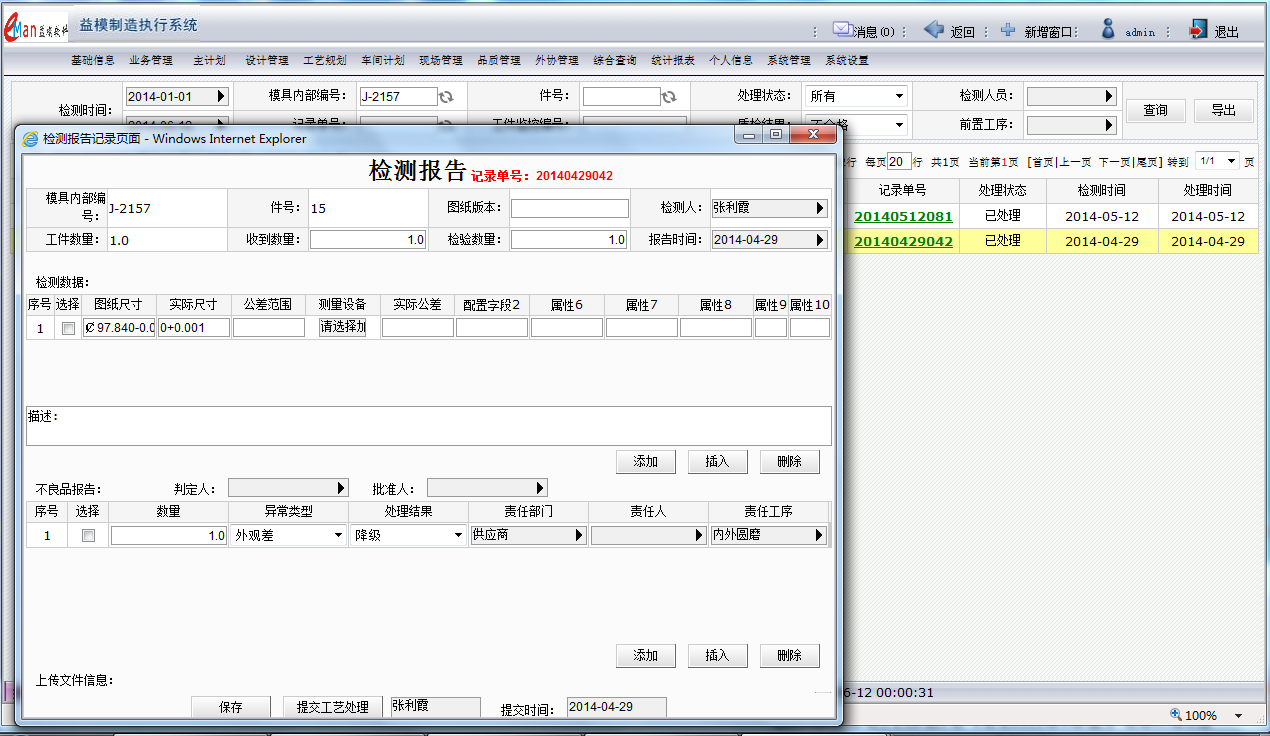

Mold quality accident information

Mold inspection reports